muffle furnace banner

vacuum brazing furnace banner0322

vacuum induction melting furnace

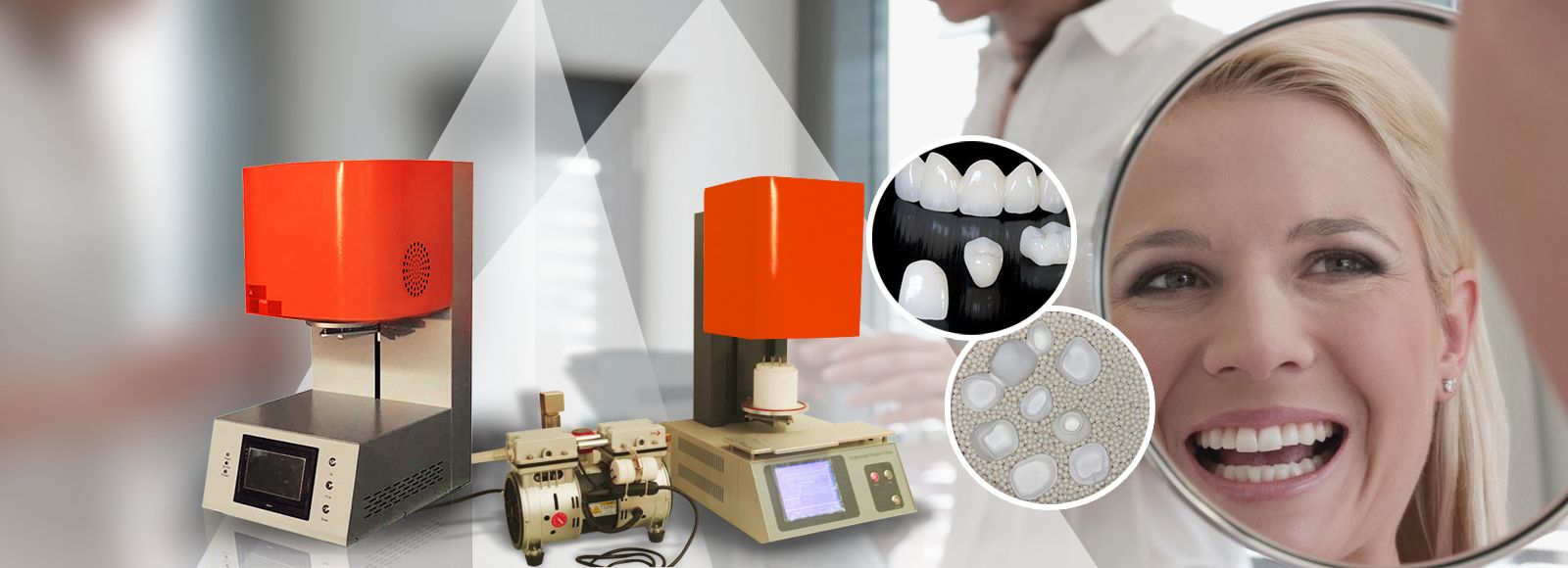

dental furnace banner

tube furnace banner

sic mosi2 heating elements banner

Brother Furnace is the leading manufacturer of High Temperature Furnaces and Heating Elements in China. As a manufacturer with more than 20 years’ experience in thermal engineering, Brother Furnace offers the wide and deep range of furnaces worldwide including Muffle Furnace, Vacuum Furnace, Dental Furnace, Tube Furnace, etc. Satisfied customers in more than 30 countries offer proof of our commitment to excellent design, quality and cost-effectiveness. Learn more